10 min read

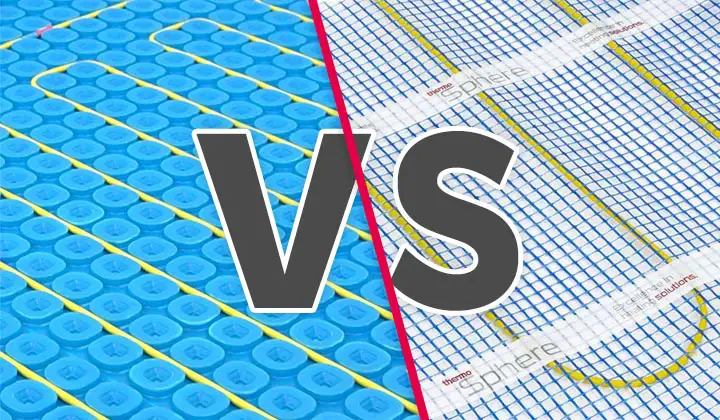

ThermoSphere Ultimate® vs ThermoSphere Mesh – what’s better for tiles?

When deciding what type of system is best to heat tiled floors, we often get asked why we suggest ThermoSphere Ultimate over ThermoSphere Mesh and...

6 min read

Chris Hedges

:

Feb 20, 2024

Chris Hedges

:

Feb 20, 2024

If you are researching the feasibility of electric underfloor heating for your home, you may see a lot of examples that simply talk about underfloor heating in bathrooms or kitchens. However, electric underfloor heating can be used within any room, even those with a carpet floor finish. In this heating blog, we’ll guide you through the following key points to ensure that the best system for the project is selected.

There are a wide range of floor finishes that are compatible with underfloor heating. However, some flooring types, such as porcelain tiles, are better suited than others because they’re more efficient at conducting and storing heat.

Porcelain and ceramic tiles

These types of tiles are often, the most popular floor finish and in most cases a more affordable alternative to stone floor tiles. The thickness of the tile has little impact on heat output. However, sometimes thicker finishes (up to 20mm) can increase the heat up time whilst the heat transfers through, but the plus side being that they hold the heat for longer. Most internal floor tiles are roughly 10mm – 12mm thick which is ideal for underfloor heating.

Natural stone

Natural stone is a superb floor finish to use with electric underfloor heating because it conducts and stores heat brilliantly. If you want to use natural stone, the majority of suppliers will advise which options are best for underfloor heating. The most common options are:

Solid timber

This option is usually a natural hardwood which has been treated and cut into boards to be used for flooring. When using these types of boards for underfloor heating, look for narrow kiln-dried floorboards because they have lower moisture content. A key point to remember with solid timber boards is that the higher the moisture content the bigger the risk of the floor warping or bowing. So, the lower the moisture, the better.

Engineered wood

Man-made, engineered wood combines a solid hardwood timber finish with a plywood backing. The laminated structure of the board helps high quality engineered floors withstand natural expansion and contraction without compromising the efficiency of the electric underfloor heating system. Cheaper engineered wood options can swell over time because they have a softer core which tends to absorb more moisture and any swelling can cause a failure of the floor covering. Therefore, so we recommend that you consult the flooring manufacturer before fully installing an underfloor heating system.

If you choose an engineered wood floor, it’s generally recommended that the board ratio of thickness to width should be in the range of 7 to 11. For example, an engineered wooden board with a thickness of 16mm and width of 160mm would give a ratio of 10 which is perfect.

Vinyl

Vinyl flooring such as Karndean provides an affordable alternative to other floor finishes and is a popular choice of floor covering for open plan living rooms. High-quality vinyl floors are hard wearing which makes them ideal for high traffic areas such as living rooms. When running electric underfloor heating with a vinyl floor finish, we recommend a maximum floor temperature of 27oC to help avoid any damage or discolouration.

Carpet

Although it isn’t common, you can use electric underfloor heating under carpet. If you do go down this route, there are some important points to be aware of.

There are four common types of electric underfloor heating systems which are traditional pre-spaced mesh mat, heating and decoupling, foil, and in-screed systems. You’ll also notice when looking at what different brands have to offer, some have more features than others which makes installation easier. We also recommend looking at the small print when it comes to the warranty. Different brands have different warranty durations and some cover significantly more too. For total peace of mind, always go for a system with a lifetime warranty where possible.

Pre-spaced mesh mat systems – Tile or stone floor finishes

A length of heating cable is attached to a mesh mat at regular intervals and it’s a more traditional system compared to others. The better mesh systems have a self-adhesive layer so you can just roll out the mat and stick it down directly onto the insulation board. Also, look for a mesh system where the mat is stuck wire-side-down. This helps to protect the heating cable during installation because one accidental nick of the heating cable could make the whole system fail even before the floor covering is laid.

You’ll also find a range of outputs available. For example, ThermoSphere Mesh is available in three outputs.

100W/m2 – Works well for larger, well-insulated and commonly used rooms that require warmth for most of the day.

150W/m2 – Faster heat-up time compared to a 100W/m2 system and is the most common option to maintain an optimum temperature in rooms that have minor heat loss.

200W/m2 – Has the fastest heat up time and is more commonly found in rooms with a higher heat loss such as conservatories.

Heating and decoupling systems – Tile or stone floor finishes

A heating and decoupling system is a more recent innovation. There are two core components to the system, a decoupling membrane mat and a reel of heating cable. The heating and decoupling membrane is designed to protect tile and stone floors from cracking, lifting. It also allows the floor finish to move independently from the subfloor and reduces any risk of damage caused by expansion and contraction. Different brands of heating and decoupling membranes have different shaped studs, but all are designed to hold the heating cable securely.

A heating and decoupling underfloor heating system allows for different heating outputs. This is done by changing the spacing between the cable. For example, using ThermoSphere Ultimate, you can use a two-stud spacing to achieve an output of 195W/m2 (perfect for wet rooms) and a three-stud spacing to achieve an output of 130W/m2 (great for well-insulated spaces).

A great thing about ThermoSphere Ultimate is that you can use it with any popular heating and decoupling mat such as Schluter-DITRA-HEAT, which gives installers the best of both worlds.

Foil systems – Wood, carpet or vinyl floor finishes

A foil system is purposefully designed to warm floating floor finishes such as wood, carpet or vinyl and are installed without having to use adhesives. Foil systems such as ThermoSphere Foil, provide brilliant thermal conductivity and fast heat up times because the electric heating cable is wrapped by two layers of foil which is an ideal thermal conductor.

Foil systems from different brands look similar but there are subtle differences which make the efficiency and practicality better than others. For example, exposed cable loops for faster installation and the system being fully earthed straight out of the box.

In-screed systems – Any floor finish

More commonly used in new build or extension projects because the heating cable can easily be installed within the screed layer during the building phase of the project. In-screed electric heating systems also take longer to install compared to electric underfloor heating mats, so it’s wise to use a pre-spaced fixing profile for a faster and more secure installation. When installing the cable, ensure to keep at least 50mm of space between each run of heating cable and the heating cable does not touch or cross over. You can’t go wrong with installing perimeter foam either, because it allows the screed to expand and contract when heated.

In-screed systems are a good fit for rooms that are in almost constant use as they have longer heat up and cool down times. For the most cost-effective use, take advantage of low-cost energy tariffs like Economy 7.

Once you have decided what type of electric underfloor heating system you are going to install, you need to consider the output of the system. The standard output for an electric underfloor heating system is around 150W/m2, but you need to consider the heating requirement of the room, so you don’t under or overheat the space.

High heat loss room such as conservatories will need a higher output to maintain a comfortable level of warmth (around 200W/m2). Whereas well-insulated rooms will better suit lower outputs such as 100W/m2.

Just like any other heating system, it’s never a bad investment to get a heat loss calculation to ensure you can reach the ideal comfort level in the room. Alternatively, there are free tools available on the internet such as City Plumbing’s Heat Loss Calculator.

There’s a simple calculation to use when working out how much electric underfloor heating you need for each room.

Floor Area (m2) – Area taken up by fixed units (m2) = Total Underfloor Heating (m2)

What do we mean by fixed units?

Let’s take the example of a bathroom. The fixed units would include the bathtub, sink and toilet. Fixed units and any type of flat-bottomed furniture such as bookcases restrict airflow to the floor which causes something called ‘thermal blocking’ which is detrimental to the floor covering. One of the most common examples of thermal blocking is discolouration of the floor finish. Therefore, always calculate for fixed units and flat-bottomed furniture when calculating how much electric underfloor heating you need for your project.

Any room within a home is suitable for electric underfloor heating. The main considerations are the type of system to use (depending on floor finish) and the output required.

If you have any questions about what’s been covered in this heating blog article, please contact us via the website or give one of the team a call on 0800 019 5899.

10 min read

When deciding what type of system is best to heat tiled floors, we often get asked why we suggest ThermoSphere Ultimate over ThermoSphere Mesh and...

9 min read

When you ask a group of people if electric underfloor heating can be used as a primary heat source, more often than not you’ll get a mix of...

6 min read

Kitchens are usually the most used living spaces in any home and are often not just for cooking but for entertaining in too. For the ‘heart of the...