8 min read

7 tips before buying electric underfloor heating

If you are in the market for an electric underfloor heating system for your next home renovation, then you have landed in the perfect place. We’ve...

One of the biggest problems tradespeople face is repairs and snagging. For electrical underfloor heating installers, these are most commonly caused by the hot-to-cold cable connection known as the “joint”.

But, by going back to the drawing board and changing the way electrical underfloor heating cables are manufactured, we’ve been able to streamline these joints and get rid of all the snagging and repairs the bulky joints cause.

This is a win for installers and customers, as snagging is currently increasing in cost and volume. Below we share how our award-winning membrane heating cable, ThermoSphere Ultimate® helps combat these issues.

Across the industry, the cost of materials is increasing, with heating installation materials rising the most. According to the UK’s material price index for new homes, the average cost of materials has gone up by 9.5% year on year. The greatest rise was in thermal and acoustic insulation, which increased by 35% and is an essential component for all electrical underfloor heating projects.

Returning to fix issues is becoming more expensive too. According to Energy Performance Certificate (EPC) data, 252,000 new homes were built in 2022, the highest figure since 2007. Given that each new home has an average of 157 snagging issues, the costs to installers and the industry are significant.

The problem of repairing work isn’t limited to new homes. The latest figures on home improvement disputes show that installers and other tradespeople are spending a lot of time and money dealing with customer complaints. For example, 43% of tradespeople spend between two and five hours a month dealing with customer complaints, and more than one in ten (11%) spend more than ten hours each month. In the worst cases, this can lead to legal action. According to research from Dispute Assist, almost two-fifths (36%) of contractors have previously had unhappy customers make a court claim against them

There are several ways for electrical underfloor heating installers and contractors to address these issues, including legal representation and other types of mediation. However, these can be costly for contractors and installers. They also fail to address the issue before it arises, so customers in new and old homes will still be left with snags and repairs.

Commenting on the range of options for installers our own Sam Hills, Product and Innovation Lead, explains, “If installers must return to a job, it costs them time, money, and their reputation. It’s no good simply passing the cost on to the customer. They’re still left with electrical underfloor heating that needs to be fixed. The best way to avoid snags and repairs is to stop them before they happen. And the best way to do that is through product design. By getting to the heart of the matter through product design, electrical underfloor heating installers won’t need to ever worry about potential snags or repairs.”

Sam and his product design team aren’t the only industry experts calling for more innovation. According to the 2022 BDO report Navigating Construction’s Challenging New Landscape, the number one way to improve confidence in UK construction is through the adoption of innovative technologies.

So, electrical underfloor heating installers should look to embrace new technologies and innovations that can help avoid repairs or snagging while building confidence in the sector. That’s why we’ve manufactured first and only in-line joint and TwistedTwin heating cable, ThermoSphere Ultimate®, a new cable innovation that installers urgently need.

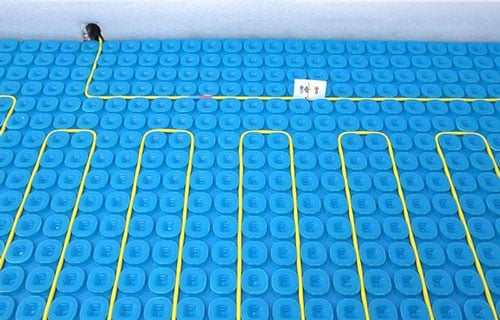

The connection or “joint” between the hot underfloor cable and the cold cabling running to the thermostats is one of the main points of failure in electric underfloor heating installations. The reason is because of their size. In normal cables, the joints are three times larger than the cables. So, when it comes to laying the cable, installers must cut into the membrane mat, insulation, and subfloor to accommodate them.

There’s no other choice than to make holes for the joints, but this causes many problems including:

ThermoSphere Ultimate® is designed to avoid all of these issues, while also significantly increasing installation speed.

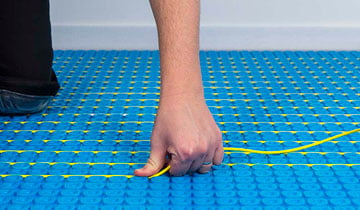

We redesigned the cable and the way it's manufactured. Instead of manufacturing two cables (hot and cold) and then connecting them during a secondary manufacturing process like other companies do, we do it all in one. We create the joints during the primary manufacturing process, which makes them in-line and results in a cable that is uniform in thickness from end to end. This removes the need for cutting holes in membranes and floors – the cause of most repairs.

By using innovative heating cables like ThermoSphere Ultimate®, installers can save themselves the costs of repairs and snagging by addressing the root cause of the problem. They can avoid spending several hours each month dealing with customer complaints or issues while also significantly increasing the efficiency of their installations. In fact, we’re so confident in our new membrane heating cable, it comes with guaranteed reliability, so there's little to no chance of the cable failing when installed correctly. Should the underfloor heating system fail in the first twelve months of installation, because of a manufacturing fault, we will not only replace the system, we’ll also replace the floor covering too.*

ThermoSphere Ultimate® is the first and only cable to combine TwistedTwin construction and in-line joint technology, making it the strongest and most robust cable on the market. Explore more of the benefits of ThermoSphere Ultimate® installation.

If you have a question about anything covered in this article or a more general question about ThermoSphere’s range of electric heating please contact one of the ThermoSphere team who will be happy to help.

8 min read

If you are in the market for an electric underfloor heating system for your next home renovation, then you have landed in the perfect place. We’ve...

10 min read

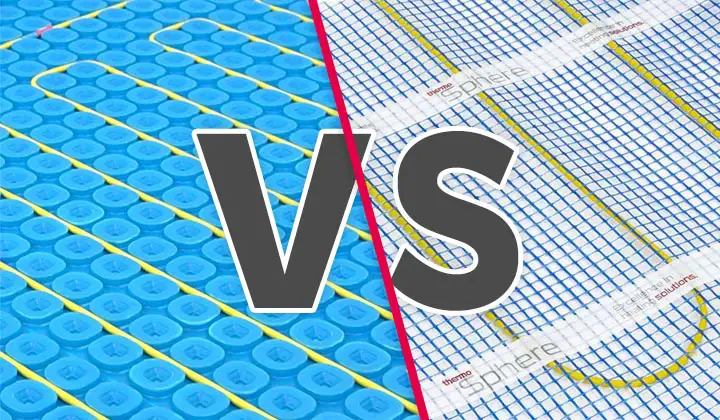

When deciding what type of system is best to heat tiled floors, we often get asked why we suggest ThermoSphere Ultimate over ThermoSphere Mesh and...

9 min read

When you ask a group of people if electric underfloor heating can be used as a primary heat source, more often than not you’ll get a mix of...