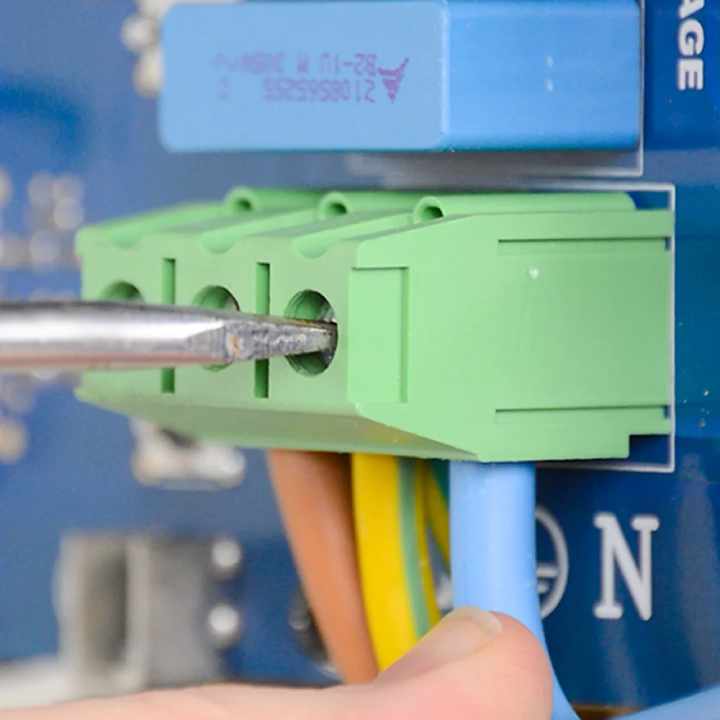

1. Install power supply

Compact and easy to install

The compact design of the Micro Electric Boiler means that it can be installed easily in the smallest of spaces.

Key installation steps

2. Mark and fix to the wall

3. Connect water feeds

4. Wire up

5. Flush and prime

6. Set temperature and enjoy!

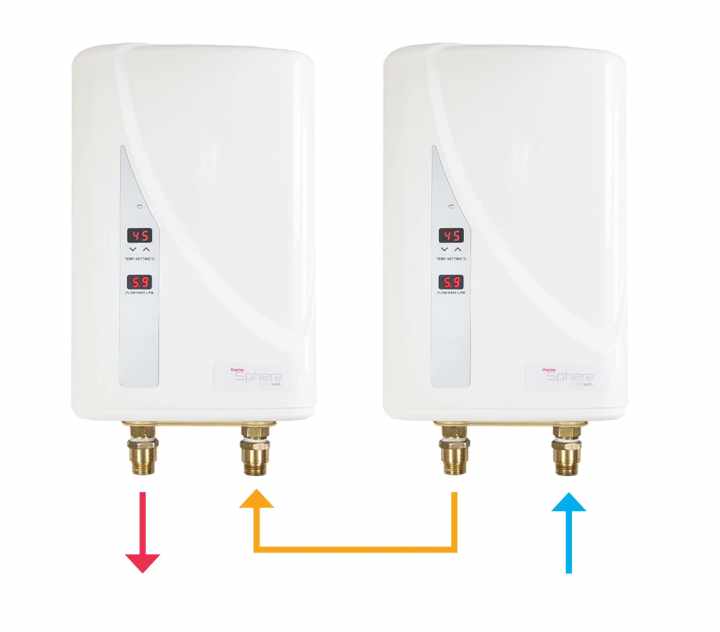

Is one enough?

A single Micro Electric Boiler can achieve flow rates of up to 5.6 litres per minute at a 25°C temperature rise. If that’s not enough you can install 2 units in tandem to achieve up to 11 litres per minute.

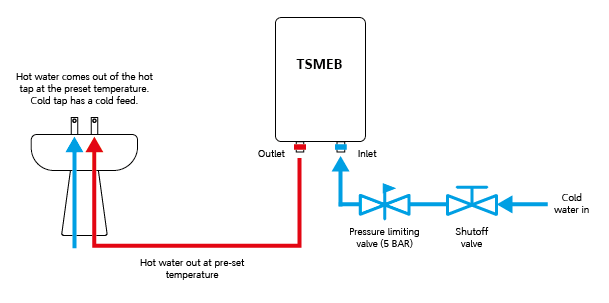

Domestic hot water systems

On demand domestic hot water such as kitchen taps and bathrooms, with temperature limiting creating safe environments. Such as care homes, where a limit of 43°C is set for hot water temperatures for the safety of residents.

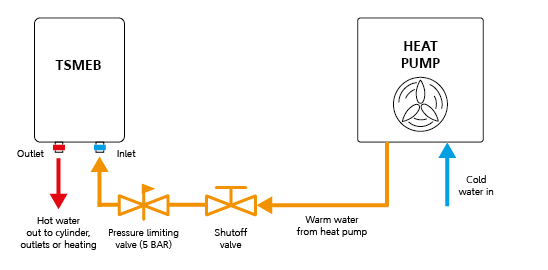

Solar thermal and heat pumps

A 100% efficient ‘top up’ for solar thermal and heat pump systems, allowing the heat pump to be set to run at optimum efficiency.

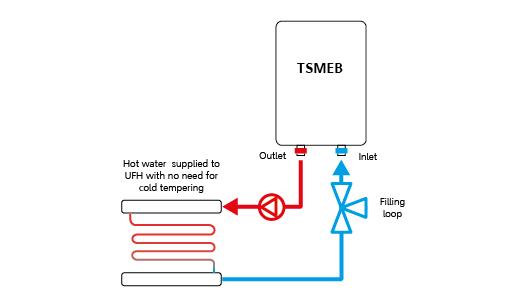

Wet underfloor heating systems

Providing hot water, at the exact temperature needed, for wet underfloor heating systems – no mixing required! A perfect fit for any type of residential and commercial project where space is at a premium.

Electrical supply

Depending on which output you choose you will need to provide a dedicated electrical supply of between 20 - 40amps. You'll also need to run suitably sized cables to handle the load and install an RCBO to protect the circuit.

Water pressure

The incoming cold water supply must be protected by a 5 BAR pressure limiting valve and a shutoff valve. There's no need to install an expansion vessel.

Fixing points

Make sure you use the existing fixing points at the four corners of the mounting boss on the Micro Electric Boiler. Do not drill any extra holes as this will void the warranty!

Have an installation question?

If you have a question that needs an answer, our comprehensive FAQs page is packed full of them. However, we know that some questions are more complex than others so our team are always available to help.