8 min read

7 tips before buying electric underfloor heating

If you are in the market for an electric underfloor heating system for your next home renovation, then you have landed in the perfect place. We’ve...

Construction costs in the UK are increasing at a steady rate. In March 2023 the material price index for new homes had a year-on-year increase of 9.5%, meaning the costs of materials were adding almost 10p more to every pound spent. The largest increase in construction material costs was thermal and acoustic insulation, soaring some 35% on the previous year.

To deal with these issues, contractors, M&E contractors, and developers can engage in systematic value engineering: not as a cost-cutting exercise, but as a tactical approach to giving their customers more value for money. This is especially true for heating, where reliable, cost-effective and modern heating solutions can also be used to deliver higher quality products.

Google ‘value engineering’ and you’ll be told that it is the “systematic and organised analysis of the value of a product or project based on its functionality and cost”. This is quite a long-winded way to describe a natural step in many product design and construction projects. Whether or not people do it formally, they’re likely to be doing it casually, as it simply involves weighing up the different costs and benefits for the products they use.

The aim of value engineering is to preserve the functionality and quality of a project while finding alternative methods and materials that can decrease the cost. In essence, by doing it, you can identify areas where there are unwanted, or inflated costs, and remove them.

For successful value analysis, it’s important to engage the right team of people. You need the right suppliers, with expert knowledge, who can help to scrutinise specified solutions and work through alternatives.

When done right, value engineering gives you two crucial benefits:

There are six stages to a detailed value engineering analysis, each requiring the input of different types of expertise. However, broadly, there are three ways to achieve the benefits of value engineering for your heating projects.

Substitute products

In a typical scenario, you can identify products of similar quality with similar functionality but are less expensive than the products the designer or architect has specified. When working with clients, to find alternative products, we use the “S.L.I.M. methodology”, which looks at: Supply Chain, Logistics, Installation, and Material Budget.

By focusing on the supply chain and sourcing products manufactured closer to the project, customers can save around 12% of the product cost and remove the risk of site delays caused by importers. And, by helping customers with a material budget consultation, we can correctly match their budgets for electric underfloor heating with the alternatives, helping them save up to 60% of the cost while maintaining the quality.

Substitute processes

While the product cost may stay the same, by engaging with a supplier or expert in a specific system, you can use a product with a significantly quicker installation. This is the Installation phase of our S.L.I.M. methodology and we’ve found that up to 50% of time on site can be saved when M&E Contractors have a consultation with one of our Project Consultants. A prime example for time saving would be which underfloor heating system you use.

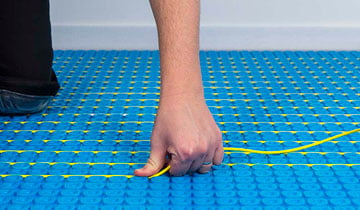

Value engineering underfloor heating can be difficult because of the specific operational requirements of the system. It’s not often likely that you could effectively “mix and match” parts from different systems. However, by changing systems to one with faster installation, you can save on installation costs and install more heating in a shorter timeframe. ThermoSphere’s Membrane Heating Cable is an underfloor heating system that doesn’t have bulky hot-to-cold cable connections in its cables. Instead, it has in-line joints that create a cable that is uniform in thickness. This means that when it comes to installation, installers do not have to use tools like Stanley knives or grinders to create cavities in the floor to accommodate the bulky connections. Which allows them to simply thumb-press in the cable in one easy step. This allows the reduction in installation time to be passed on to your customers as a cost saving, and it drastically de-risks the process, meaning there’s less chance of returning to a site to repair or replace a system if it is damaged during installation.

Uncover new value

In an ideal scenario, when you are engaged in value engineering, you can actually propose products that are better quality or have more functionality. In heating projects, this can often happen with similar items with different warranties. For example, if electric radiators have been specified in a multi-storey apartment building, M&E contractors may be able to specify alternative radiators that meet the same functionality requirements and have the same efficiency, but which come with a longer warranty. One example is the ThermoSphere Oil Filled Radiator which comes with 10 years chassis warranty and a 5-year electricals warranty. If the specified oil radiators had only 4 years warranty, then the end-user gains greater value.

While value engineering might sound a bit like cost cutting because reducing costs is central to the process, it is very different in reality. Cost cutting implies that you’re not particularly interested in preserving the quality or functionality of a product. You’re just trying to find ways to save money, and in the process, you are forced to make sacrifices. Cost cutting is short sighted and should be avoided. It leads to poor quality work and often increased costs down the line when low quality products drive up costs by not performing optimally.

A common example that many heating installers are familiar with is cost cutting on insulation. As prices have increased, some homeowners are asking installers to remove the insulation for their underfloor heating projects. The request, they think, will save them money. However, this isn’t right. Failing to properly install insulation as part of an underfloor heating system will compromise the system. It will leak heat into the subfloor and radiate less into the room. The knock-on effect is that it will take longer to reach the desired temperature, which will significantly increase the energy costs for the homeowner.

As newer, energy efficient and low-carbon forms of heating become more widely available, the opportunity to value engineer a heating solution to be more sustainable is increasingly realistic. Solar PV panels are more affordable than before, and when combined with electric underfloor heating and a 100% renewable energy tariff, they offer one of the most environmentally friendly ways to heat your home. As renewable energy sources fall in price, and the UK government introduces regulations requiring minimal environmental standards, the cost of future-proofing a heating solution should be high up in your value analysis.

To explore the possibilities for your next project, get an expert quote.

8 min read

If you are in the market for an electric underfloor heating system for your next home renovation, then you have landed in the perfect place. We’ve...

5 min read

One of the biggest problems tradespeople face is repairs and snagging. For electrical underfloor heating installers, these are most commonly caused...

5 min read

The UK must reach its net zero goal for 2050, and in the construction sector that requires a 68% reduction of carbon emissions by 2030.Last year we...