3 min read

Why choose the Ultimate heating cable

At ThermoSphere we’re excited to launch the new improved version of our underfloor Membrane Heating Cable. We’ve been working hard to introduce...

As purse strings continue to tighten, we’re seeing more electric underfloor heating installations without insulation board being used. Not only does this break our hearts here at ThermoSphere HQ, it also means homeowners across the UK are spending more running their electric underfloor heating system, which is inevitably unwelcomed news for them.

Considering the current financial climate, it’s understandable that there is a tendency to remove ‘non -essential’ items from project quotes to win the job, but for the homeowner, it’s a false economy.

In our first heating blog article of the year, we’ll be taking a look at the importance of insulation board for electric underfloor heating projects, what types are available and how it positively impacts running costs.

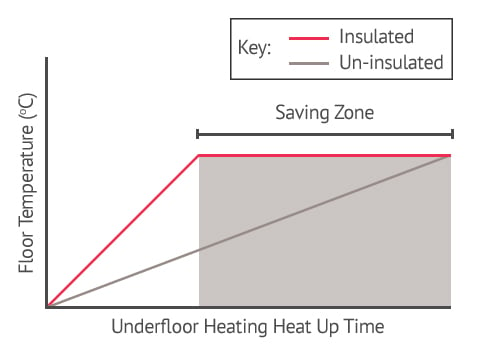

With underfloor heating, the heat that’s generated by the heating cable travels in all directions equally by conduction, until it encounters a layer that is more insulative. The underfloor heating system is ‘sandwiched’ between two layers, the substrate below which might be either timber or concrete and the floor finish above. When on, the heating cable will warm the layer below and the layer above at the same rate.

When electric underfloor heating is installed without insulation board it will take twice as long for the floor to heat up to the right temperature, as you will be losing heat energy downwards, which means that the system will cost much more to run. When we receive calls from, homeowners saying that their underfloor heating is taking too long to reach temperature, the lack of insulation board is the most common cause.

When you use insulation board as part of your electric underfloor heating installation, you’ll significantly reduce heat being lost downwards towards the substrate. Instead, most of the heat is heating the floor above which means that you’ll have the system on for less time to reach optimum temperature which reduces the running cost of the electric underfloor heating system. Actually, insulation board improves the efficiency system efficiency by up to 50%!

There certainly are!

As well as making the whole system more energy efficient and faster heat up times, insulation boards help to:

Enhance comfort

By including insulation boards, you will help to maintain perfectly consistent and comfortable floor temperatures throughout. Insulation boards also help to reduce cold spots by ensuring that there’s an even distribution of heat.

Reduce impact sound

One of the common paths of noise is hard floors such as tile, stone, laminate and engineered wood which don’t include isolation material between the floor covering and floorboards. This is particularly significant in blocks of flats where hearing your neighbour’s footsteps is not uncommon and it many cases can become increasingly annoying. The addition of insulation boards help reduce impact sound from footsteps or furniture movement on the floor above.

You’ll find lots of different brands and thicknesses of insulation board available in the market. However, for your electric underfloor heating insulation there are two types to consider; uncoated and coated. But how do you know which type to use for your project?

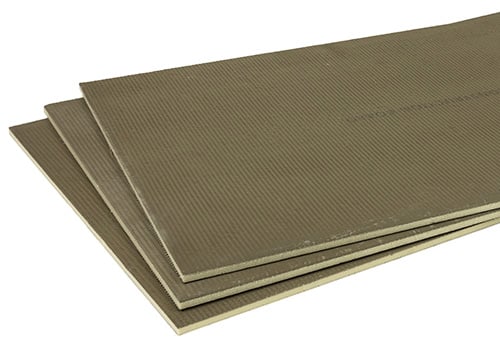

Uncoated insulation boards

This type of insulation board is a cost-effective thermal insulation for concrete and screed substrates. ThermoSphere’s uncoated insulation boards are manufactured from a high-density extruded polystyrene and can be installed using a flexible cement-based tile adhesive. The ideal thickness to use is 10.5mm but if you need to reduce the height of the floor build-up, you can use a 6mm board.

Coated insulation boards

Coated insulation boards have a high-density extruded polystyrene core with a fibreglass reinforced cement coating on both sides. As well as adding rigidity, strength and thermal insulation to timber substrates, they’re water resistant and rot proof which makes coated insulation boards a great choice for wet environments such as bathrooms and wet rooms.

What thickness of insulation board is best?

There are two things to consider before buying insulation board:

When quoting insulation board, the industry average thickness is 10mm, which we usually recommend.

How to secure the board to the substrate

Firstly, make sure the substrate is secure, clean and free of dust and grit. Use flexible adhesive in accordance with instructions and spread it using a notched trowel. Ensure that you spread enough adhesive for one insulation board at a time because it prevents adhesive drying before it’s able to be laid.

When laying the board onto the adhesive, take care in squeezing out any air pockets. For the best finish, make sure that all boards are flush and tape over the joints using reinforcing tape. Once completed, you’re ready for the underfloor heating system to be installed.

Cutting the board

Should you need to cut the board to size, you can simply cut it with a sharp blade or a hand saw.

How to secure the board to a timber substrate

The same as uncoated insulation boards, ensure the substrate is secure, clean and free of dust and grit. Lay the boards on the floor space and fix them in place using appropriate fixings such as 32mm fixing screws and metal fixing washers.

We recommend using 8-10 mechanical fixings per board, fixing in the middle of the board as well as round the perimeter and then join to the adjacent board. This will maximise the strength and lateral stability of the floor. For the best finish, make sure all boards are flush, and then tape over the joints using reinforcing tape.

Cutting the board

Coated insulation boards can easily be cut with a sharp blade or a wood saw.

If you are installing these insulation boards in a wet room project, you should use tanking paste to fully waterproof the room before laying the electric underfloor heating system.

If you have any questions about insulation and what floor build-up to use for your next electric underfloor heating project, please contact us via the website or give one of the team a call on 0800 019 5899.

3 min read

At ThermoSphere we’re excited to launch the new improved version of our underfloor Membrane Heating Cable. We’ve been working hard to introduce...

9 min read

Electric underfloor heating: a no-nonsense guide for first-timers, fixers and installers Smart homeowners know that the best way to stay ahead of...

8 min read

If you are in the market for an electric underfloor heating system for your next home renovation, then you have landed in the perfect place. We’ve...