9 min read

Electric underfloor heating vs wet underfloor heating – what's better?

It’s great that you are thinking about installing underfloor heating for your next project. You’ll receive all the benefits that come with underfloor...

4 min read

Chris Hedges

:

Feb 2, 2022

Chris Hedges

:

Feb 2, 2022

I recently asked our wonderful Customer Experience team what were the typical questions asked by homeowners when they called us. Unsurprisingly, one of the most frequent questions was ‘Why is my underfloor heating taking so long to heat up?’ Upon analysing this ‘underfloor heating crime scene’ the cause, 99.9% of the time, was that the underfloor heating system had been installed without insulation boards.

Now, you may be thinking that insulation boards are a nice-to-have or are just another money-making gimmick, however, you’d be wrong. In this article I’ll walk you through several evidence-backed points as to why leaving out insulation boards is doing a disservice to the quality of your underfloor heating installation and your pocket.

If you are short of time and need an answer now, you can contact our customer experience team who will be able to help.

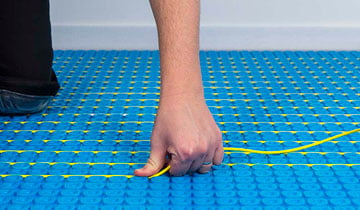

Let’s take electric underfloor heating as an example, the heat generated travels in all directions equally by conduction, until it encounters a layer that is more insulative. In the build-up for a tiled floor finish, you have the substrate below the heating cable and flexible tile adhesive with beautiful tiles above. When you install underfloor heating without insulation board, the heating cable will warm the layer below and the layer above at the same rate. Because of this, it will take twice as long for the floor to heat up to the right temperature, as you will be losing heat energy downwards, which means that the system will cost much more to run.

By including insulation board in the build-up, you’ll significantly reduce heat being lost downwards towards the substrate. Instead, the majority of the heat is heating the floor above which means that you’ll have the system on for less time to reach optimum temperature and that saves money on the overall running costs. In fact, installing insulation board can improve the efficiency of an electric underfloor heating system by 50% or more.

It’s not just reducing heat loss that insulation boards are great at. Additional benefits include:

What it means for installers

One of the main challenges of using insulation boards is the minor addition to floor height it gives. This is particularly challenging in retrofit projects where floor height is fixed and can’t be ‘designed in’ as simply as a new build project. As difficult as this may be, when quoting an underfloor heating system, installers should always quote insulation board, because ultimately the experience of having underfloor heating with it will be much better for the homeowner than without it.

What it means for homeowners

I touched upon this earlier in this article but it really is a key point that needs reinforcing. Including insulation board for your electric underfloor heating installation will make it up to 50% more efficient. Therefore, saving energy, money and time spent on the phone going through troubleshooting tips with the retailer or manufacturer.

Yes. Including insulation board will increase the installation cost, but if you want to feel the real benefit of the heating and keep your running costs to a minimum, it’s definitely worth including. Without, it would be like having a cup of lukewarm coffee. Mediocre at best and not that enjoyable (especially with the milk skin on top).

There’s a wide range of insulation boards available from many brands which include Wedi, Heat Mat and, of course, ThermoSphere. However, when it comes to underfloor heating, there are two types to consider; uncoated and coated. But which type should you use for your project?

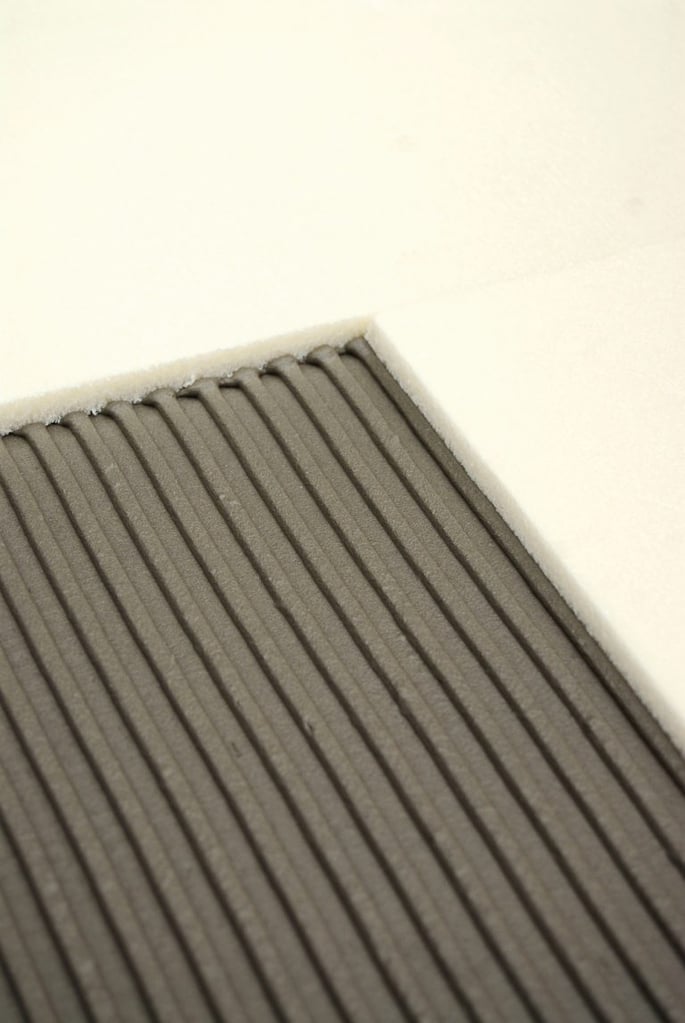

Uncoated insulation boards

This type of insulation board provides a cost-effective thermal insulation for concrete and screed substrates. They are manufactured from a high-density extruded polystyrene and can be installed using a flexible cement based tile adhesive.

Coated insulation boards

Coated boards are manufactured from a high-density extruded polystyrene core with a fibreglass reinforced cement coating on both sides which adds rigidity, strength and thermal insulation to a timber substrate. These boards are water resistant and rot proof which makes them a great choice for wet environments such as bathrooms and wet rooms.

What about the thickness of board?

Before you hand over the cash for the insulation board, there are several points to consider which will help you choose the right board thickness for your project.

When quoting insulation board, we usually recommend an insulation board with a minimum thickness of around 10mm. This also tends to be the industry average.

Cutting the board

If you need to cut the board to size, you can simply cut uncoated insulation board with a sharp blade or a hand saw.

Securing the board to the concrete substrate

Ensure your substrate is secure, clean and free of dust and loose particles. Mix flexible adhesive in accordance with instructions and spread using a notched trowel. Spread enough adhesive for one board at a time to prevent adhesive drying before the board is able to be laid.

Lay the board onto the adhesive taking care to squeeze out any air pockets in the adhesive. For a high-quality finish make sure all boards are flush and tape over the joints using reinforcing tape. Your floor is now prepared and ready for the underfloor heating system.

Cutting the board

You can easily cut coated insulation boards with a sharp blade or a wood saw.

Securing the board to the timber substrate

Ensure your substrate is secure, clean and free of dust and loose particles. Set out your cut boards onto the floor space and fix in place using appropriate fixings. We recommend 32mm fixing screws and metal fixing washers.

Allow about 8-10 mechanical fixings per board, fixing in the middle of the board as well as round the perimeter and the join to the adjacent board. This will maximise the strength and lateral stability of the floor.

For a high-quality finish make sure all boards are flush, and tape over the joints using reinforcing tape.

Waterproofing

If you are installing these insulation boards in a wet room, you should use tanking paste to fully waterproof the room before laying the underfloor heating.

I hope that this article has helped you to decide on using insulation board within your underfloor heating installation. If you want to feel the true benefit of underfloor heating and conserve energy, it’s a no-brainer.

If you still have questions, our team are on hand to help answer them. Head to the contact us page to start the conversation.

9 min read

It’s great that you are thinking about installing underfloor heating for your next project. You’ll receive all the benefits that come with underfloor...

6 min read

Tiled floors are the most common floor finishes to have over electric underfloor heating and for good reason. Electric underfloor heating is more...

8 min read

If you are in the market for an electric underfloor heating system for your next home renovation, then you have landed in the perfect place. We’ve...